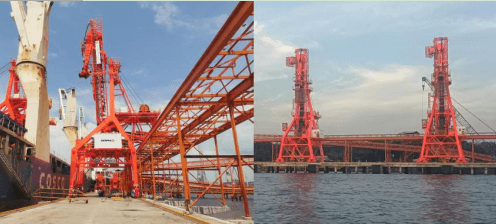

Recently, RHM successfully delivered two GENMA ship-loaders designed and built for overseas old customers at the Indonesian bulk cargo terminal, providing support for coal loading.

The two GENMA loaders provided by RHM this time have efficient loading capacity, with a rated conveying efficiency of up to 4000 tons/hour. The equipment adopts an efficient operating process, including dock belt conveyor, tail truck, ship loader arm conveyor, swinging chute, and throwing device. These components work together to easily achieve efficient loading operations for 15000~120000DWT bulk carriers。

In terms of structural design, the equipment adopts a unique A-type gantry structure, which has the characteristics of light weight, strong wind resistance, and strong adaptability to terminal infrastructure. This structure ensures the stability and reliability of the equipment during loading and unloading operations, and can provide reliable loading support for customers.

· Flexible and efficient

In addition to its unique gantry structure, the swinging chute and rotary throwing device are also one of the highlights of the GENMA ship-loader. The swinging chute of the equipment adopts a dual hydraulic cylinder drive system, which can achieve flexible swinging of the chute by precisely controlling the expansion and contraction of the hydraulic cylinder, thereby expanding the loading range and reducing the number of movements of the loading machine, improving the loading efficiency.

The rotary throwing device works in coordination with the swinging chute, and releases loose cargo into the cabin through rotation and throwing of materials, ensuring uniform distribution and stable delivery of materials, effectively avoiding material accumulation, and making the loading process smoother.

· Environmentally protection and practicality

Not only that, GENMA ship loaders also have the characteristics of environmental protection and practicality. The two GENMA ship loaders provided to the customer this time are equipped with air conditioning condensate water collectors, which can collect condensate water and replace the ground water supply system to achieve the utilization of recycled water and save water resources. This environmentally friendly design further enhances the sustainability and resource utilization efficiency of GENMA ship loaders.

Comfortable and safe

In terms of driving experience, the GENMA ship loader cab is equipped with a hydraulic cylinder balance system, which can ensure that the operator maintains stable operation during the loading process and obtains a good operating experience. At the same time, a broad field of vision enables operators to clearly observe the operation of the loading machine, ensuring operational safety.

RHM has been deeply involved in the field of port machine for more than ten years, focusing on providing customers with port loading and unloading related supporting equipment to help the prosperity and development of the port industry. GENMA ship loaders can meet customer needs and bring more value in terms of efficiency, stability, and environmental friendliness. Choose GENMA and experience the future of efficient shipment.